The industrial fasteners market plays a pivotal role in the global manufacturing and construction industries. Fasteners—such as nuts, bolts, screws, rivets, and washers—are essential components that hold machinery, structures, and equipment together. Despite being small in size, they are critical for the integrity, durability, and functionality of countless products across industries like automotive, aerospace, construction, electronics, and heavy machinery.

This article explores the current landscape of the industrial fasteners market, analyzes key growth drivers, identifies emerging trends, and offers a forecast of its future trajectory.

Market Overview

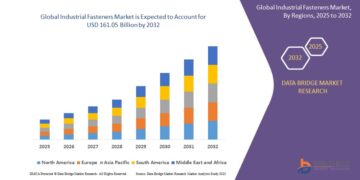

The global industrial fasteners market has experienced steady growth over the past decade, driven by the expansion of end-use industries and technological advancements in manufacturing processes. According to various market reports, the global industrial fasteners market size was valued at over USD 80 billion in 2023 and is expected to reach USD 110 billion by 2030, growing at a CAGR of around 4.5% during the forecast period.

Fasteners are available in a wide variety of materials including steel, aluminum, brass, titanium, and plastic. Steel fasteners dominate the market due to their strength, durability, and cost-effectiveness. However, increasing demand for lightweight and corrosion-resistant alternatives, particularly in aerospace and automotive applications, has led to a rise in demand for non-metallic and specialty fasteners.

Key Market Segments

1. By Material

- Metal Fasteners: Account for the majority of the market share, especially carbon steel and stainless steel variants.

- Plastic Fasteners: Gaining traction due to their resistance to corrosion, lightweight properties, and application in electronics and automotive sectors.

2. By Product Type

- Externally Threaded: Such as bolts and screws, widely used in construction and manufacturing.

- Internally Threaded: Like nuts, typically paired with bolts.

- Non-threaded: Including rivets and washers, used in aerospace and automotive industries for permanent joining.

3. By End-use Industry

- Automotive: A major contributor, using fasteners in vehicle assembly and engine components.

- Construction: Growing infrastructure projects globally drive demand.

- Aerospace: High-strength, lightweight, and temperature-resistant fasteners are crucial.

- Machinery: Industrial equipment and tools rely heavily on fasteners.

- Electronics: Miniaturized fasteners for devices and circuit boards.

Market Drivers

1. Infrastructure Development

Global urbanization and the rising need for residential, commercial, and industrial infrastructure are significant growth drivers. Governments are investing heavily in construction and transportation projects, especially in developing nations across Asia-Pacific and Latin America.

2. Automotive Production and Electric Vehicles

As global vehicle production increases and the electric vehicle (EV) segment expands rapidly, the demand for innovative, lightweight, and high-performance fasteners continues to rise. EVs, in particular, require specialized fasteners to support battery assemblies and lightweight materials.

3. Technological Advancements

Innovations in materials science and manufacturing technology are transforming the fasteners industry. Smart fasteners, which incorporate sensors to monitor structural health, are being developed for use in aerospace and defense applications.

4. Demand for Lightweight Materials

Industries are focusing on reducing product weight for energy efficiency and performance—especially in aerospace and automotive sectors—driving demand for composite, plastic, and titanium fasteners.

Market Challenges

1. Fluctuating Raw Material Prices

The volatility of steel, aluminum, and other raw material prices impacts production costs and profit margins. Manufacturers are under pressure to manage supply chains and pricing strategies efficiently.

2. Environmental Regulations

With rising concerns over carbon emissions and sustainability, manufacturers face stricter regulations on production processes, especially in regions like Europe and North America. This necessitates investment in eco-friendly materials and processes.

3. Standardization and Quality Compliance

Global players must comply with various international standards (ISO, DIN, ANSI) for safety, quality, and compatibility. Ensuring uniformity while catering to diverse regional requirements poses a challenge.

Regional Insights

Asia-Pacific

The Asia-Pacific region dominates the global industrial fasteners market, driven by high manufacturing output in China, India, Japan, and South Korea. The region’s growth is supported by rapid urban development, increased automotive production, and the presence of numerous OEMs and Tier 1 suppliers.

North America

The United States holds a substantial share due to strong demand in the automotive, aerospace, and defense industries. The region is also at the forefront of technological innovation and product customization.

Europe

Europe shows steady growth, backed by its well-established automotive industry and increasing adoption of sustainable manufacturing practices.

Latin America & Middle East

These regions are emerging markets with growing construction activities and infrastructure development, which will gradually increase demand for industrial fasteners.

Emerging Trends

1. Smart Fasteners

Integration of IoT-enabled sensors in fasteners for monitoring load, stress, and temperature in real-time is gaining popularity in aerospace, defense, and heavy engineering.

2. Sustainability and Green Manufacturing

Manufacturers are adopting energy-efficient production methods and using recyclable materials to align with global sustainability goals.

3. 3D Printing and Customization

Additive manufacturing (3D printing) is being explored to produce customized fasteners with complex geometries for specialized applications.

4. E-commerce and Digital Supply Chains

Digital platforms are transforming procurement and distribution in the fasteners market. Online catalogs, digital twins, and real-time inventory tracking are enhancing operational efficiency.

Future Outlook

The future of the industrial fasteners market looks promising, supported by innovation, rising demand across sectors, and global infrastructure development. Manufacturers are expected to focus more on product customization, advanced coatings for corrosion resistance, and sustainable practices.

Investments in R&D and strategic partnerships among players will likely intensify to meet the evolving needs of various industries. Regions like Asia-Pacific and Africa are expected to emerge as lucrative markets due to their growing industrial bases.

Conclusion

While industrial fasteners may appear simple, they are indispensable components that support some of the world’s most complex and critical industries. As technology evolves and industries continue to push for higher performance, safety, and efficiency, the fasteners market is poised for transformation. Companies that embrace innovation, sustainability, and digitalization will lead the way in shaping the future of this dynamic market.

Read More : https://www.databridgemarketresearch.com/reports/global-industrial-fasteners-market